battery Energy Storage

Technical Advisory

Commissioning & Validation

Service & Optimization

Who are we?

We are electrical and mechanical engineers from diverse backgrounds, united by our industry experience and a shared goal: to combine our expertise and create something exciting and valuable.

Our core focus is industrial-scale energy storage systems (ESS).

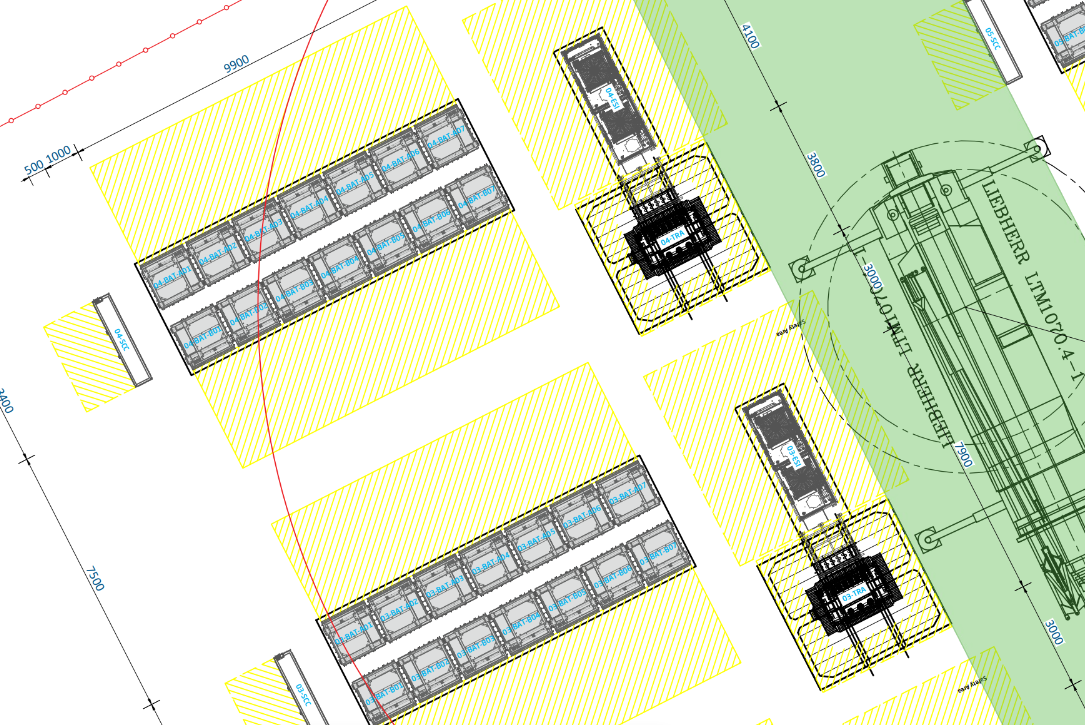

With years of hands-on experience across Europe, we have worked on a wide range of systems—spanning from 300 kW/kWh to 80 MW/MWh—in various stages including factory acceptance test, provision of civil works, commissioning, testing, troubleshooting, capacity optimization, and maintenance.

What are we good at?

During design and manufacturing phase

Design review – early identification and correction of conceptual design errors

Power plant sizing support – assisting in capacity planning and system design

Risk reduction – minimizing technical and operational risks from the early stages

Support in main equipment selection – technical comparison of technologies and vendor proposals

FAT (Factory Acceptance Test) verification – overseeing and verifying equipment testing at the manufacturer’s site

During Civil works, installation and commissioning

On-site monitoring, coordination, and optimization of execution processes

On-site diagnosis and resolution of technical issues

Independent expert quality control inspections

Capacity, performance, and efficiency testing

Cell voltage balancing analysis

Right before handover, during operation

- Verification of contractual technical compliance

Review of the execution plan

Operation & Maintenance (O&M) recommendations

Maintenance (if alloved by supplier)

On-site diagnosis and resolution of technical issues

Capacity assessment

State of Health (SoH) calculation

How can we support your project?

Design phase, before construction

Concept design

- From the very beginning of your project, we spot design and conceptual issues early—problems that, if left unnoticed, can lead to costly delays and threaten your project timeline.

Selection and review of main parts

- Choosing the right supplier among many can be challenging. We guide you through the process by highlighting key technical criteria, filtering out unsuitable technologies, and revealing potential shortcomings that suppliers often overlook or avoid mentioning. By asking the right technical questions, we ensure the best partner is selected for your project.

Factory acceptance test

- To ensure the product meets the expected quality and European standards, we are available to participate in the Factory Acceptance Test, regardless of its location (typically in China).

During project execution

Construction and installation

- Throughout the civil works and installation, we provide ongoing on-site supervision and technical inspections to guarantee your plant is constructed according to the design, European and local standards, and meets the highest quality expectations.

Commissioning

- With many years of hands-on commissioning experience, we offer comprehensive oversight throughout every stage of the process. From initial setup to final validation, we ensure that all systems and devices are correctly configured and fully operational. Our expertise allows us to identify and address unexpected hardware or software issues early on, minimizing delays and supporting efficient, timely resolution. This proactive approach ensures a smooth, reliable, and successful commissioning outcome.

Communication protocols

We supervise or establish the communication between your equipment supplier and the plant’s control system, ensuring seamless integration. We recommend well-structured signal exchange lists and perform thorough testing to validate the stability and reliability of communication protocols such as Modbus (RTU/TCP), IEC 61850, and OPC-UA. Our goal is to ensure that all interfaces function smoothly and consistently under real operating conditions.

Validation, accreditation

Site acceptance test

- Before project handover, we provide comprehensive test protocols that confirm your technology delivers the promised usable capacity, performance, response times, and operational stability. We verify SoC calibration and ensure cell voltage balance to maintain optimal system health and fully comply with contractual requirements.

TSO/DSO accreditation

- We conduct accreditation tests in full compliance with local, country-specific grid operator requirements. Following the testing, we prepare a comprehensive and well-documented report that meets all regulatory standards, ensuring a smooth approval process and reliable grid integration.

Operation and maintenance

Operational optimization

- Once the installation and commissionig is completed, we can offer tailored recommendations for efficient plant management to maximize battery life and perform necessary maintenance.

State of health measurement

- Each year, we can measure key performance indicators—capacity, output, and thermal regulation—so you have a clear picture of your plant’s health and efficiency.

Maintenance

- With the supplier’s approval, we can recommend and carry out maintenance procedures as needed. Timely execution of these tasks contributes to a longer, more stable operational lifespan of the system.

Lets talk about it!

Have an upcoming project where our expertise could help?

Curious about our services or just want to connect?

We’d be happy to hear from you — let’s start the conversation.